Material Analysis

Benefits

- By using Cleanpart analytic capabilities, customers can get precise data about their material, surfaces and media.

- The obtained characterizations are used in multiple contexts, from qualification of new processes, new parts or new services up to failure analyses, troubleshooting or yield/process/efficiency improvements.

- Our understanding of the applications, processes and parameters allows us to deliver an accurate and appropriate interpretation of the analytical results data to support our customers' innovations or to assist them in their operational tasks.

The Cleanpart engineering team is composed of skilled engineers and specialists in chemistry, material and surface science.

Cleanpart sites are equipped with their own laboratories for sample preparation and optical analyses performed on various materials such as metals, alloys and ceramics.

We also work with a network of partners, labs and universities that provides us with characterization means. Ultimately, we supply our customers a comprehensive analytical capability tailored to their needs.

- Fourier transform infrared (FTIR) spectroscopy:

- Polymer characterization

- Analyses of defects in organic materials

- Inductively coupled plasma mass spectroscopy (ICP/MS): detection of all chemical compounds and traces in a single sample

- Atomic absorption spectroscopy (AAS): used for trace analyses

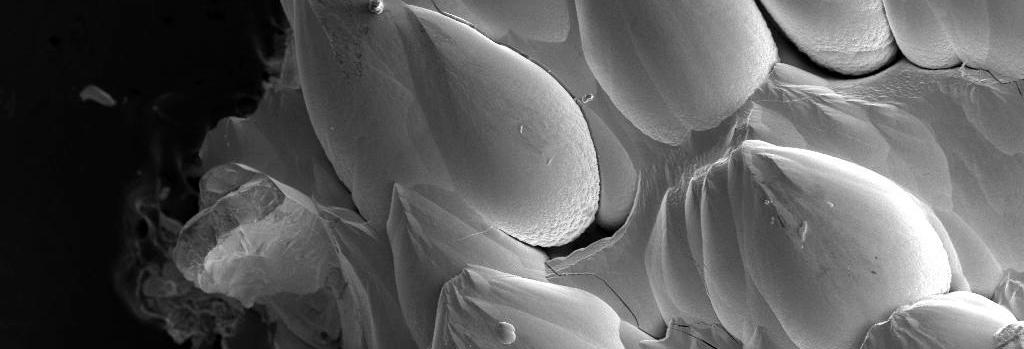

- Scanning electron microscopy (SEM): for surface characterization

- X-rays diffraction (XRD): a powerful technique to identify the crystal structure of a material (metals and ceramics)

- Measurements of the texture of polygrained materials

- Measurement of strain-stress of materials

In addition to material analyses, Cleanpart is also able to perform mechanical tests that often complement the micro-characterization of the material:

- Compressive/tensile tests

- Bending tests

- Hardness or micro-hardness tests

- Microsection