Electrical Arc Spray Coating

The glass industry uses thin coatings on float glass for their different properties such as anti-reflection, anti stain, protection...These coatings are deposited in vacuum equipement, often by PVD process. For some applications, the coatings accumulated in the reactor will tend to delaminate and fall on the glass.To prevent this phenomenon from happening, Cleanpart provides glass manufacturers with surface preparation and metallic coating on their reactor shielding , dramatically enhancing the adhesion of the deposits in the chambers and hence contributing to reduce significantly the defects on the float glass plates.

Benefits

- Component life and reduced equipment cost of ownership

- TWAS operates at low temperatures and consequently allows the thermal impact on your components to remain very low, which prevents any substrate deformation

- TWAS is also used as an adhesion layer in a vacuum environment to improve

- Performance: by increasing the mean time between preventive maintenance (MTBPM)

- Quality and defectivity: by decreasing the particle levels

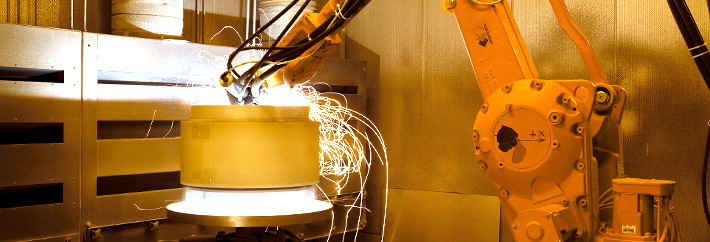

TWAS torches are robot-controlled to ensure maximum process repeatability. Our engineering teams carefully review your specifications and needs to ensure the right coatings for your applications.

Properties

- Very high bond strength , up to 5 x 10⁷ Pa ( 50 MPa )

- Thicknesses: from 50 µm to 3000 µm

- Adjustable roughness: smooth to extra rough, 10 µm to Ra = 100 µm

- High ductility with low stresses

- High density with low porosities down to 1%

Principle: The Twin-Wire Arc Spray (TWAS) process involves two wires of the material to be sprayed, a high-current (DC) power source and an atomizing gas stream. The wires serve as electrodes through which the electrical power is applied within the spray gun. The molten particles generated by the fusion of the wires are sprayed onto the prepared surface. Arc temperatures reach up to 5,000°K that causes any material to melt, whereas the component surface remains at an ambient or controlled temperature.

Sprayed material: due to the technology, only conductive materials are subjected to spraying. Chrome steel alloys, nickel alloys, SST alloys, copper, bronze, brass, aluminum and zinc are typically sprayed materials. However, it is possible to spray non-conductive materials mixed with metals (for example, cermets – combination of ceramics and metals). To do this, cored wires are produced where the non-conductive materials (such as carbon to produce carbides) is inserted into the core of the conductive wire. In this way, cermet alloys can be sprayed, which allows the layer wear resistance to be enhanced.

Sprayed layers properties: adjustable thicknesses, roughness, porosity and purity tailored to customer needs as ensured by our internal lab facilities.

Methodology: after the specifications have been defined, we implement the entire coating procedure that includes tooling, surface preparation, controls and measurements, analytics and inline testing.