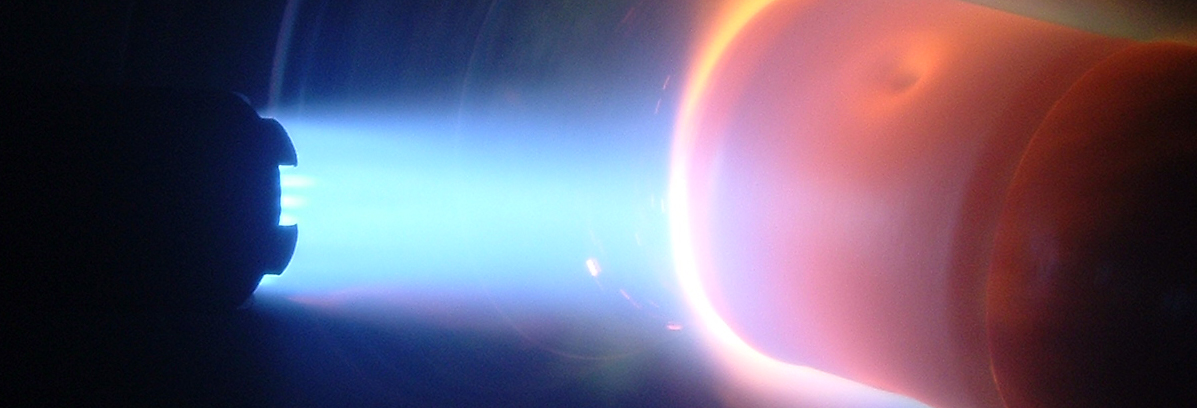

Flame Spray

Benefits

- Flexible and cost-efficient Flame Spray technology is used to provide wear, impact and corrosion resistance.

- The low-particle velocities result in coatings that are more porous and oxidized compared to other thermal spray coatings.

- Porosity of the film is not always a drawback, it can be beneficial where oil is used as a lubricant because some oil is trapped within the coating, which provides a longer life.

- Oxides in the coating increase hardness and enhance wear resistance.

- Flame Spray provides a thicker build-up for a given material compared to any of the other thermal spray processes.

- Flame spraying is also a relatively inexpensive technology.

Our engineering teams validate your specifications and needs and ensure the right coatings for your applications.

Properties

- Bond strength , up to 4,000 Psi 4 x 10⁷ Pa ( 40 MPa )

- Adjustable roughness: from smooth to extra rough, up to Ra = 75 µm

- High ductility with low stresses

- High density with low porosities (spray and fuse) to high porosity of deposited material

Principle: a flame spray uses combustion gases such as hydrogen, oxygen and acetylene as the energy source to melt the material that can be in the form of powder, wire or rod. This heat source creates a gas stream with a temperature in excess of 3,000°K. In the flame spray process the combustion stream speed and temperature are comparably lower and therefore oxidation and porosity levels of the deposited films are higher.

The flame spray process is also used in combination with material fusing in a spray and fusing process. In this case, the material is sprayed onto the component and the as-deposited coating is then fused onto the substrate, which produces a metallurgical bond. The natural porosity of the as-deposited film is eliminated and the bond strength of the protecting layer is considerably enhanced.

Sprayed material: various materials can be used in the flame spray process because of the variety of material-distribution means such as powders, wire and rods. This includes oxide ceramics, pure metals or alloys and plastics. Some of the metals that are typically applied are nickel aluminides, steel, Hastelloy alloys and also tin-based alloys.

Sprayed-layer properties: adjustable thicknesses and roughness, porosity and purity tailored to customer needs as ensured by our internal lab facilities. Components can be coated at Cleanpart sites or at customer locations.

Methodology: after the specifications have been defined, Cleanpart manages the entire coating procedure from tooling, surface preparation, controls and measurements up to analytics and inline testing.