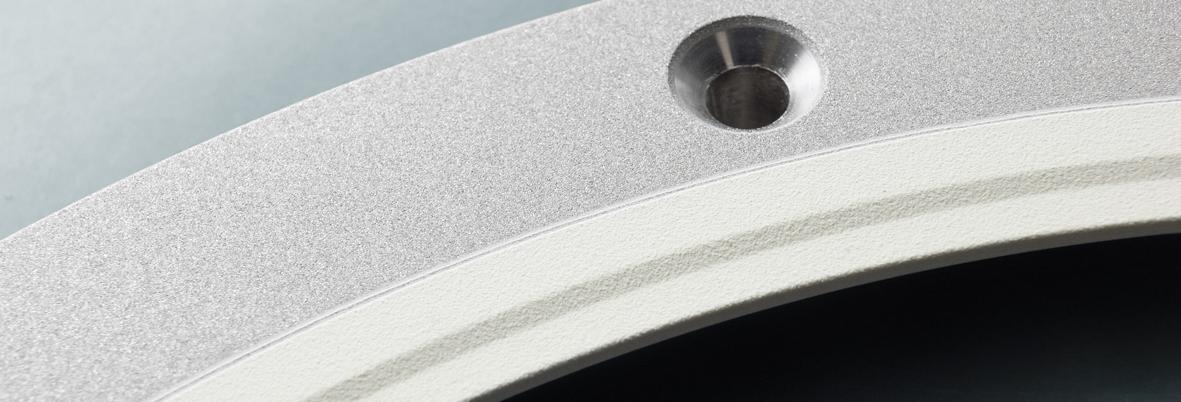

Plasma Spray Coating

Physical Vapor Deposition (PVD) Equipments shields sometimes need to be coated with thermal coatings of metals or ceramics so that the deposited layers adhere better on the shields, therefore yielding to less contamination on the customers products and extended maintenance cycles on the equipments.

Benefits

- Plasma spray coatings allow your components performance to be highly enhanced.

- Whatever criteria is important to you (heat barrier, corrosion protection, contamination reduction, osteocompatibility, component life... ) it can be improved, leading to higher equipement availability, longer component life and reduced equipment cost of ownership.

- Our plasma torch are robotic to ensure maximum process repeatability.

- Our engineering teams validate your specifications and needs and ensure adequate coatings to your applications.

Properties

- Typical thickness: 50 to 3000 µm

- Tunable Roughness depending on application: 5 µm to 30 µm Ra

- Porosity: tunable from < 1%

- Machining/polishing possible

Principle: a plasma gas is heated by an arc and accelerated through a shaped nozzle. This creates a plasma jet with a gas velocity up to Mach 2. Temperatures in the plasma jet are close to 10,000°C, which melts the respective material and allows it to be projected onto a surface where it cools and forms a layer.

Sprayed material: because of the versatility of plasma spray technology, a wide range of materials can be deposited. This ranges from low-temperature polymers up to metals, and also includes ceramics such as zirconia, yttria, aluminia, titanium- and chrome oxide, spinel and hydroxylapatite (Hap).

Properties of sprayed layers: adjustable thicknesses, roughness, porosity and purity, tailored to customer needs as ensured by our internal lab facilities.

Methodology: after the required specifications have been defined, Cleanpart implements the entire coating procedures that include tooling, surface preparation, controls and measurements, analytics and inline testing.